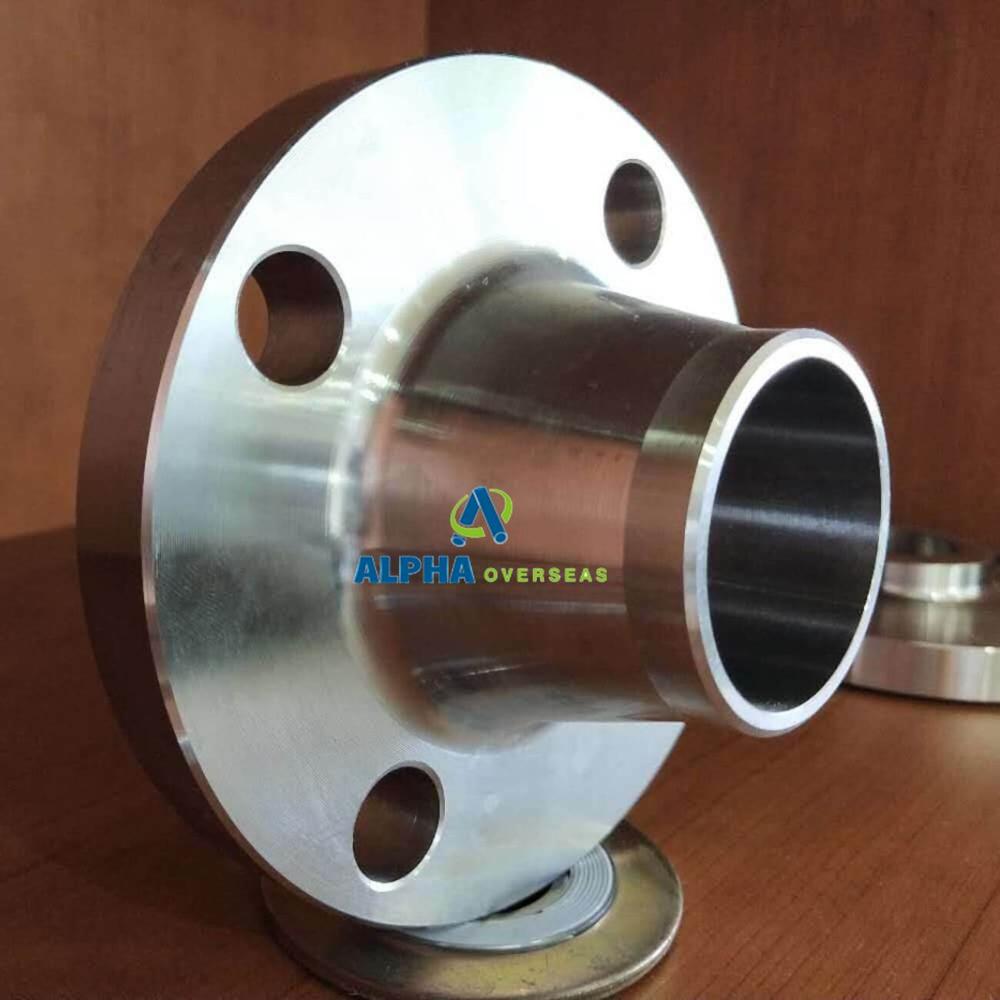

Titanium Grade 5 Weld Neck Flange

Price 500.0 INR/ Number

Titanium Grade 5 Weld Neck Flange Specification

- Features

- High Quality

- Corrosion Resistant

- Yes

- Surface Finish

- Polished

- Usage

- Industrial

- Grade

- Multple Grades Available

- Standard

- ANSI

- Surface

- Galvanized

- Size

- Various Sizes Available

Titanium Grade 5 Weld Neck Flange Trade Information

- Minimum Order Quantity

- 2 Number

- Supply Ability

- 5000 Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Titanium Grade 5 Weld Neck Flange

Experience the grandiose utility of our Titanium Grade 5 Weld Neck Flange, a best-seller in the world of industrial fittings. This lavish, corrosion-resistant flange is available in multiple redoubtable grades and various sizes to suit your distinct requirements. Each piece boasts a polished, galvanized surface and meets strict ANSI standards, ensuring uncompromised quality and longevity. Special Last Chance pricing applies for bulk orders directly from our exporter, manufacturer, supplier, and trader base in India. Choose a product that combines high-quality craftsmanship with unparalleled durability for your next industrial project.

Specific Use & Application of Titanium Grade 5 Weld Neck Flange

Titanium Grade 5 Weld Neck Flanges are ideally suited for general and specialized applications in demanding industrial environments. Their primary use is for securely connecting pipes in systems exposed to corrosive and high-pressure media, including chemicals and gases. Application places include manufacturing plants, refineries, oil and gas installations, and power generation stations, where reliability and superior performance are paramount.

Export Markets, FOB Ports & Key Certifications for Weld Neck Flange

Our Titanium Grade 5 Weld Neck Flanges are supplied globally, with main export markets spanning North America, Europe, and Asia. Transportation is facilitated efficiently via major Indian FOB ports, ensuring timely order completion and delivery at competitive sale prices. Each batch is certified to meet stringent industry standards, assuring clients of consistent quality, safety, and compliance for large-scale and bespoke applications alike.

Specific Use & Application of Titanium Grade 5 Weld Neck Flange

Titanium Grade 5 Weld Neck Flanges are ideally suited for general and specialized applications in demanding industrial environments. Their primary use is for securely connecting pipes in systems exposed to corrosive and high-pressure media, including chemicals and gases. Application places include manufacturing plants, refineries, oil and gas installations, and power generation stations, where reliability and superior performance are paramount.

Export Markets, FOB Ports & Key Certifications for Weld Neck Flange

Our Titanium Grade 5 Weld Neck Flanges are supplied globally, with main export markets spanning North America, Europe, and Asia. Transportation is facilitated efficiently via major Indian FOB ports, ensuring timely order completion and delivery at competitive sale prices. Each batch is certified to meet stringent industry standards, assuring clients of consistent quality, safety, and compliance for large-scale and bespoke applications alike.

FAQs of Titanium Grade 5 Weld Neck Flange:

Q: How is the Titanium Grade 5 Weld Neck Flange installed for industrial use?

A: Installation involves welding the neck of the flange to the pipe, which enhances strength and ensures a leak-proof connection, making it suitable for pressurized applications in various industries.Q: What benefits does the corrosion-resistant feature offer in application places?

A: The corrosion-resistant characteristic significantly extends the operational lifespan of the flange in harsh environments, reducing maintenance costs and maintaining system integrity in chemical, oil, and gas industries.Q: When should multiple grades be selected for an industrial project?

A: Selecting multiple grades is recommended when your project demands varying mechanical properties or resistance levels, ensuring optimal compatibility and durability for distinct system requirements.Q: Where are these weld neck flanges typically used?

A: They are commonly utilized in manufacturing plants, power generation facilities, oil refineries, and other settings where robust pipe connections are critical to safety and operational efficiency.Q: What is the standard process for exporting these flanges from India?

A: Our export process includes strict quality inspections, reliable packaging for safe transportation, completion of necessary certifications, and shipment from major Indian FOB ports for prompt global delivery.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Titanium Flanges Category

Titanium Grade 2 Neck Flange

Minimum Order Quantity : 100 Kilograms

Grade : Multple Grades Available

Standard : ANSI

Usage : Industrial

Surface : Galvanized

Titanium Grade 5 Slip On Flange

Minimum Order Quantity : 100 Kilograms

Grade : Multple Grades Available

Standard : ANSI

Usage : Industrial

Surface : Galvanized

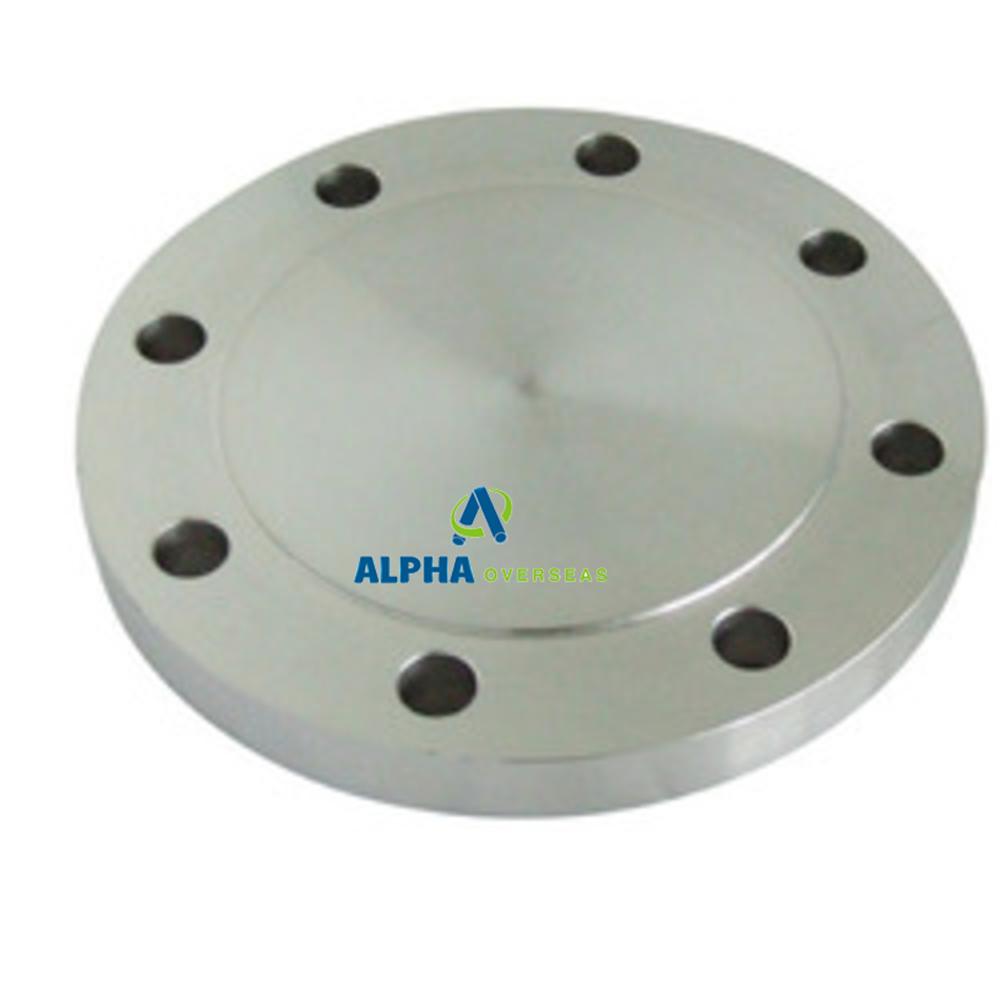

Titanium Grade 5 Blind Flange

Price 2000.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : Multple Grades Available

Standard : ANSI

Usage : Industrial

Surface : Galvanized

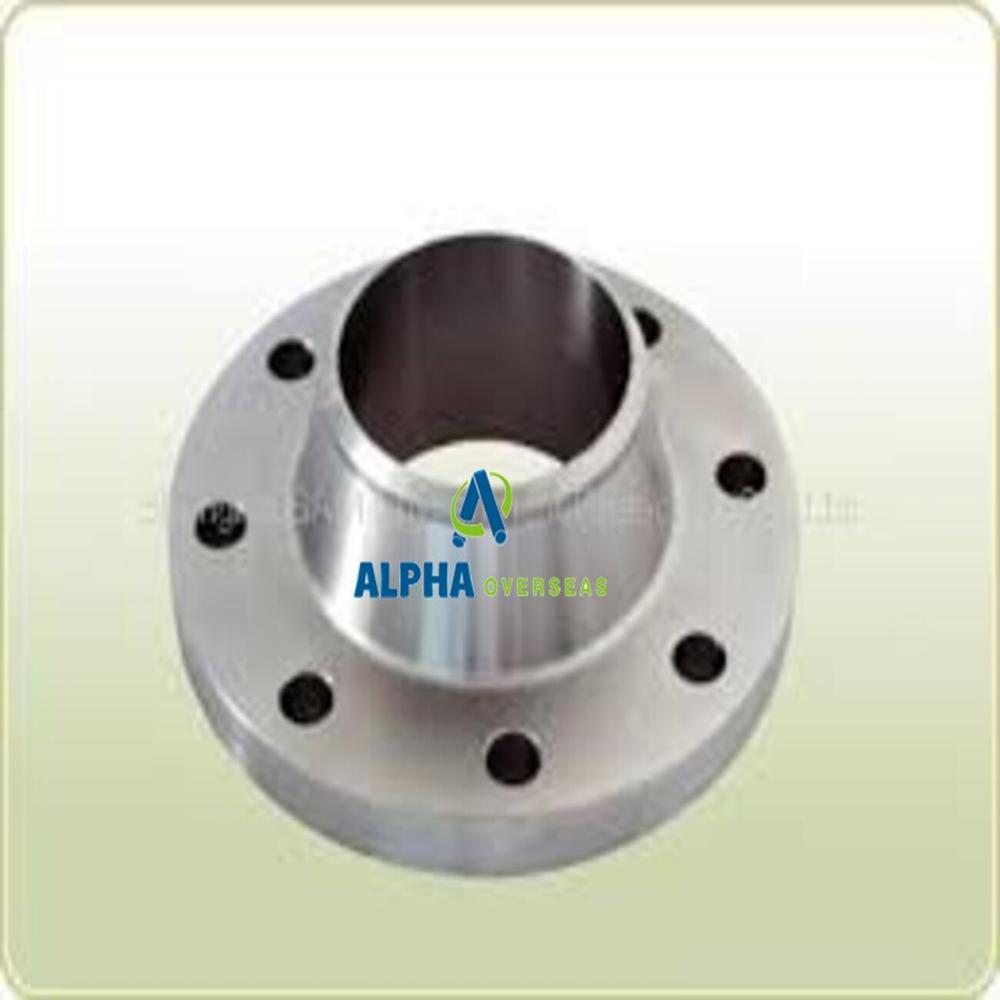

Titanium Grade 5 Long Weld Neck Flange

Price 500.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : Multple Grades Available

Standard : ANSI

Usage : Industrial

Surface : Galvanized

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry